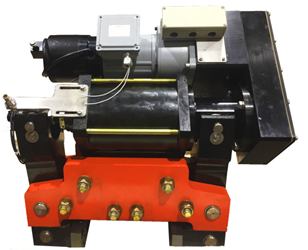

Wheel Brakes (Electric)

Wheel Brakes apply force generated by springs on both sides of crane wheels.

They minimize the amount of strain and stress on sill beams and truck assemblies of the crane.

Oversized brake shoes with bonded friction material apply on the side flanges of idler wheels, providing the friction forces, and thus, braking capacity.

Wheel brakes must be carefully sized in order to prevent the skidding of the crane caused by too much torque applied on the side of the wheel.

Adjustable Setting Time 3 - 30 sec

Holding Capacity Not Applicable

Min Paint Thickness200 - 275 µm

Benefits

Application

Benefits

- Spring Set – patented fully Electric Release

- No hydraulic components, so no environmental or fire liabilities

- Actuator holding brake in sealed enclosure and with low power consumption, keeps wheel brake pads released until power is cut-off or lost

- Setting time can be adjusted by a mechanical regulator for setting time delay from 3 to 30 seconds

- The regulator does not use friction and is free from wear

- High efficiency actuator for spring applied braking devices utilize an electro-mechanical release and hold system

Application

Applications:

- Ship to Shore Cranes

- Rail Mounted Gantry Cranes

- Automated Stacking Cranes

- Log Handling Cranes

- Wide Span Cranes

- Ship Loaders